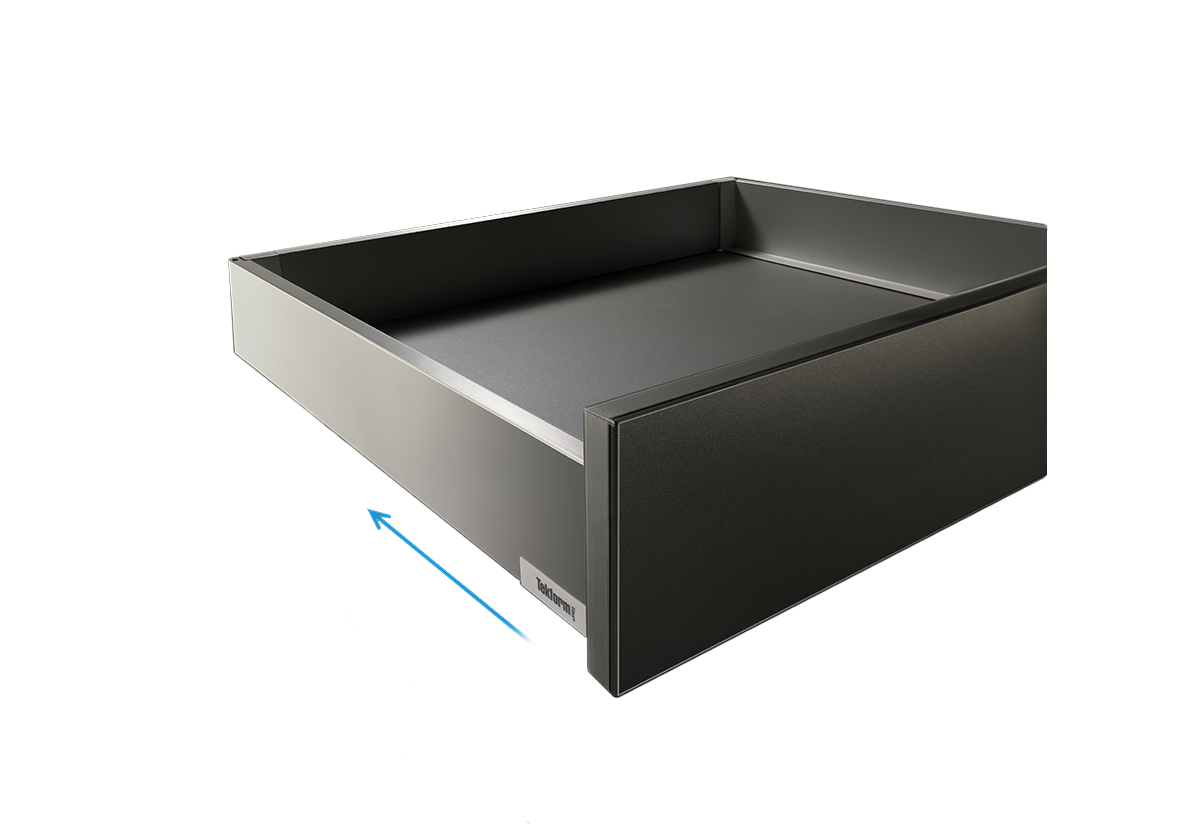

Titus Damper is a multi-purpose hydraulic damping technology for a wide range of applications in furniture, consumer appliances, interior doors, bathroom equipment, and automotive. One of the main characteristics of hydraulic damping technology is a fully programmable and controllable damping curve that enables to fine-tune performance to specific applications. The extended temperature spectrum provides operational efficiency in cooler temperatures on one side and hotter on the other side of the scale.

Hydraulic Damping Solutions

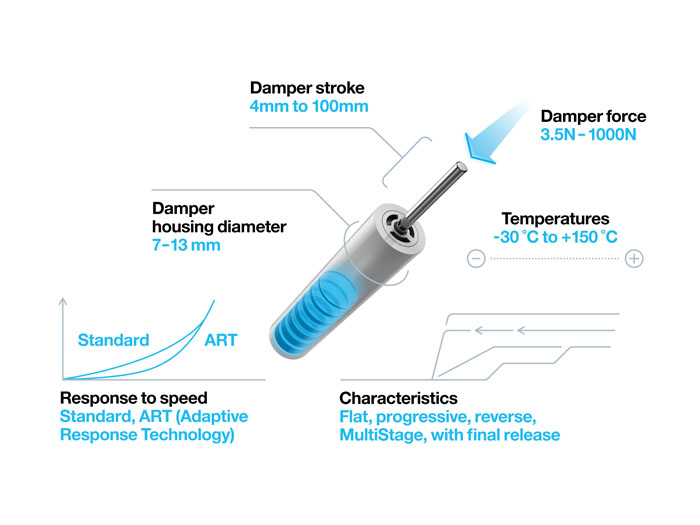

Hydraulic damping solutions for effective deceleration of objects up to 1000N and a temperature range from -22 °F to 302 °F, maintaining consistent damping in all conditions. Its fully programmable and controllable damping curve enables to fine-tune performance to specific applications.

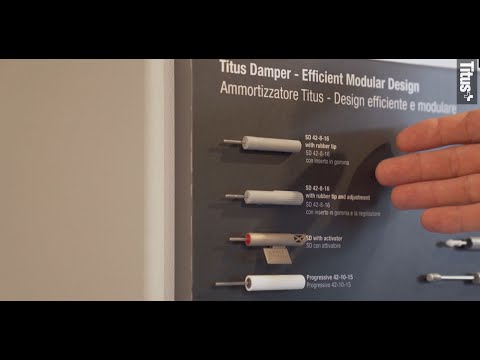

Damper range

Titus dampers assure reliable damping at any closing speed. Its efficient modular design offers quick development of customized solutions for various furniture and other applications. Hydraulic damping solutions are used to effectively decelerate objects up to 1000N with a temperature range from -22 °F to 302 °F, maintaining consistent damping in all conditions. Its fully programmable and controllable damping curve enables fine-tuning performance for specific applications.

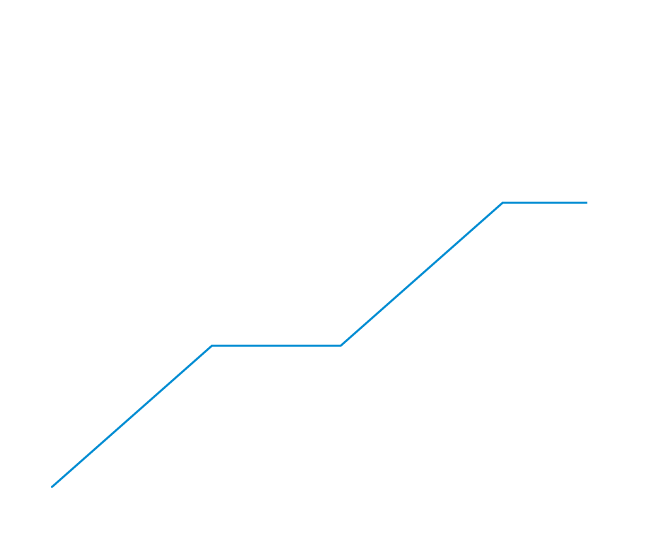

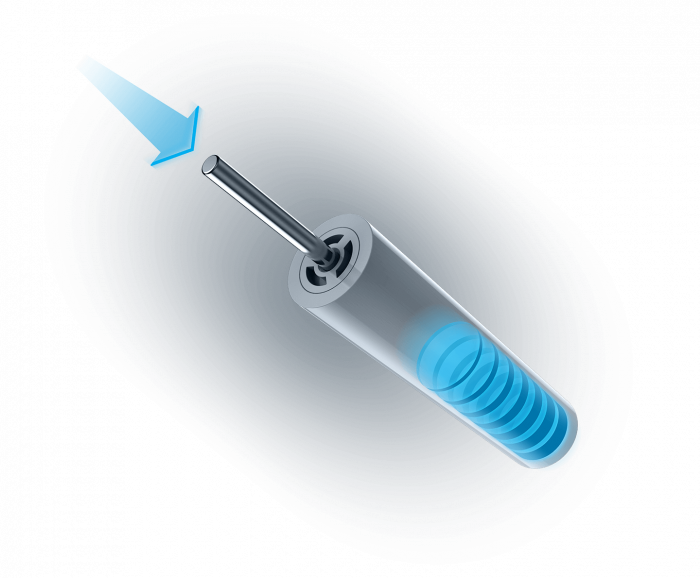

ART - Adaptive Response Technology

Enables the device to adjust to varying closing speeds. This technology optimises the damper's performance by adapting to the weight and speed of the door or drawer, adjusting the damping force accordingly. As a result, the closing is smooth, progressive, and reliable. This function also reduces the required opening force, meaning less effort to open the door.

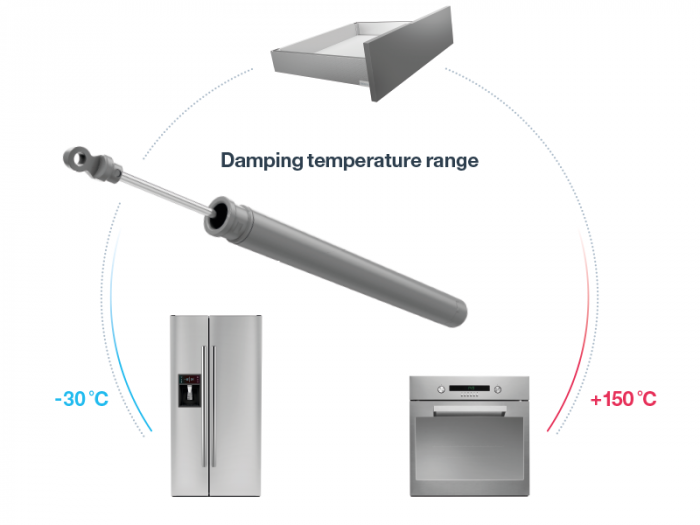

High temperature resistance

Titus dampers and damping systems work in temperature range from -30°C to +150°C. The extended temperature spectrum provides operational efficiency in cooler temperatures on one side and hotter on the other side of the scale. This can prove especially beneficial in ovens, coolers, refrigerators, and automotive industry.

Effective performance even with higher loads

Our dampers are designed to slow down the motion of objects up to 1000N. Most common applications include interior glass, lift up or heavier oven doors. All dampers can be fine-tuned to achieve smooth and even damping action on objects of various dimensions and weights.

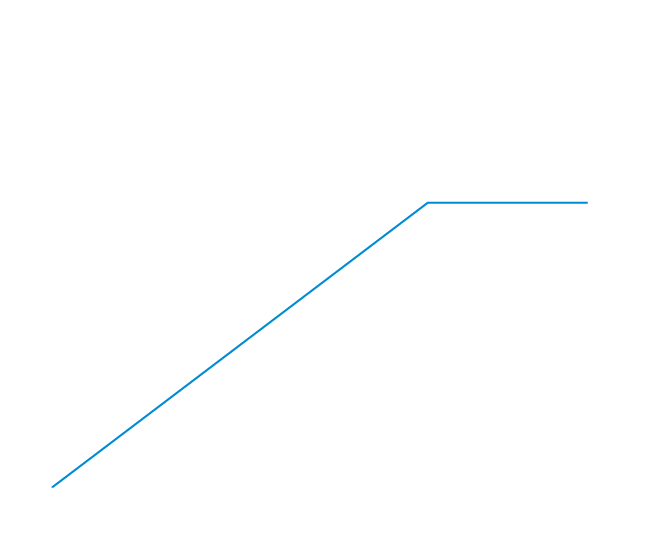

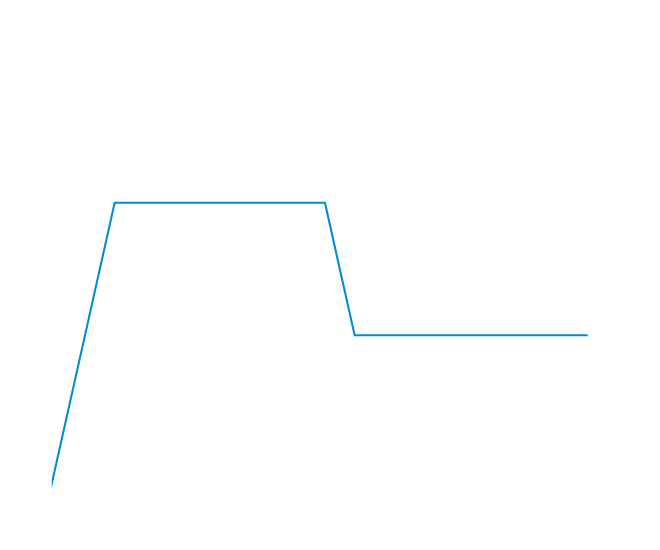

Damping action

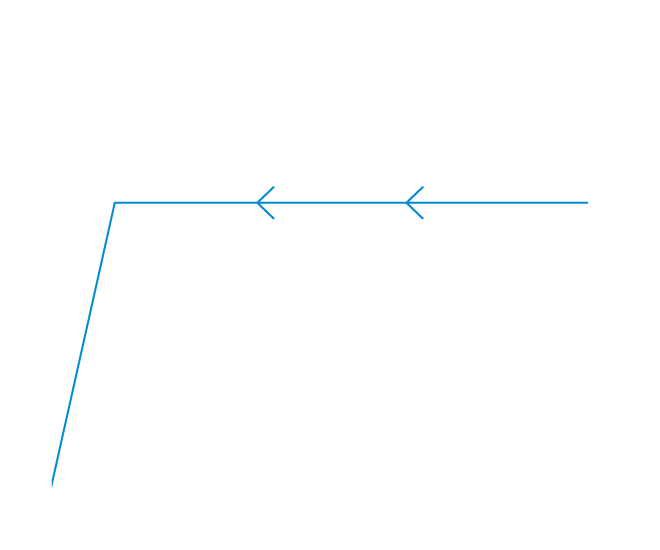

We program a damping action to precisely define forces and their distribution over the whole damping path in order to fine-tune performance to specific applications. Titus damper is designed to assure efficient damping at any closing speed, providing consistency of performance over a wide range of applications and reliability of reaching the end position regardless of speed.

Operating scope

The high coefficient of Titus damper assures efficient damping at any closing speed, even very slow. We can easily adapt damping force to your needs. The damping action is even and smooth for soft and reliable closing.

Fh - damping force at slam speed (740mm/min)

Fl - damping force at slow speed (60mm/min)

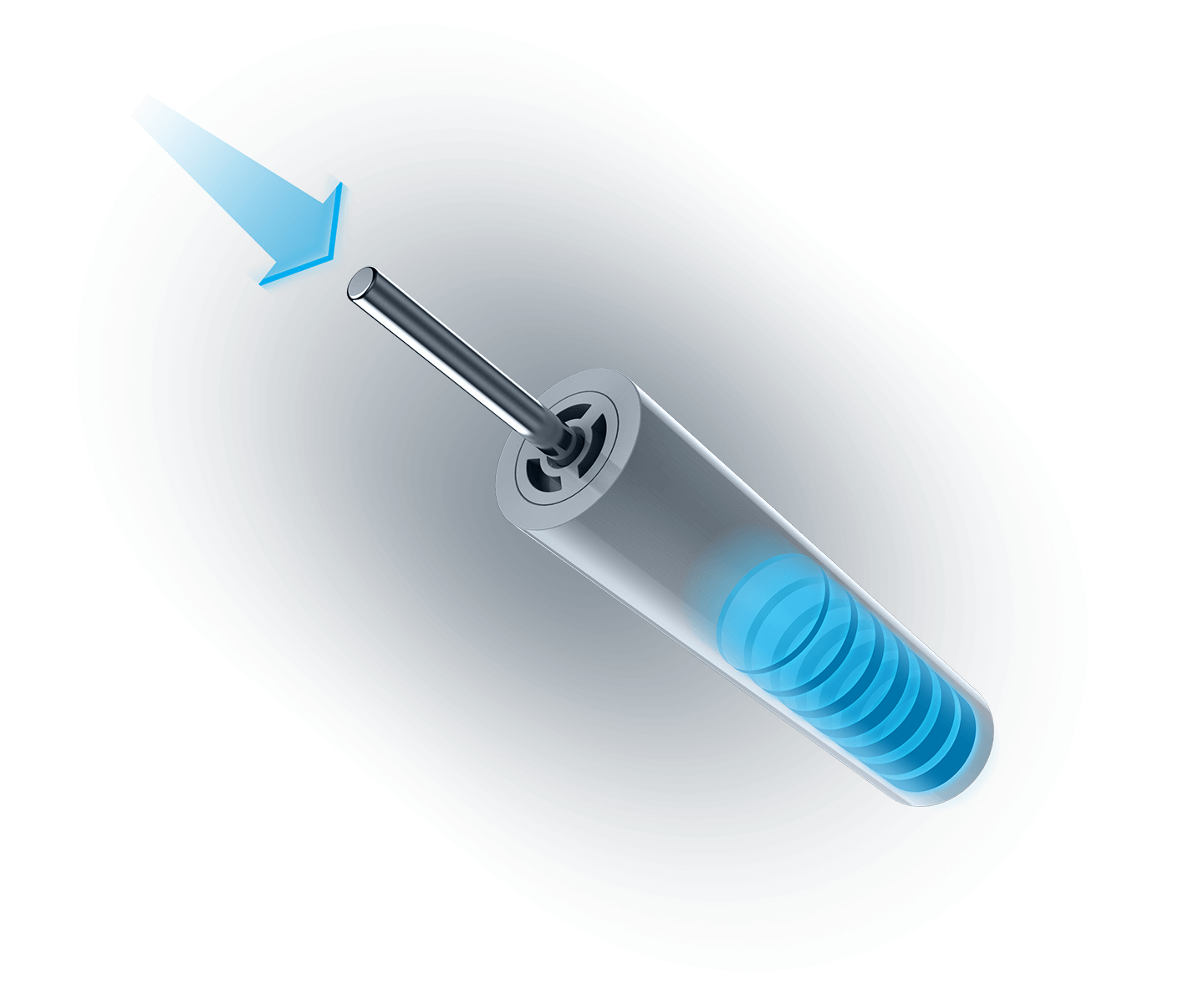

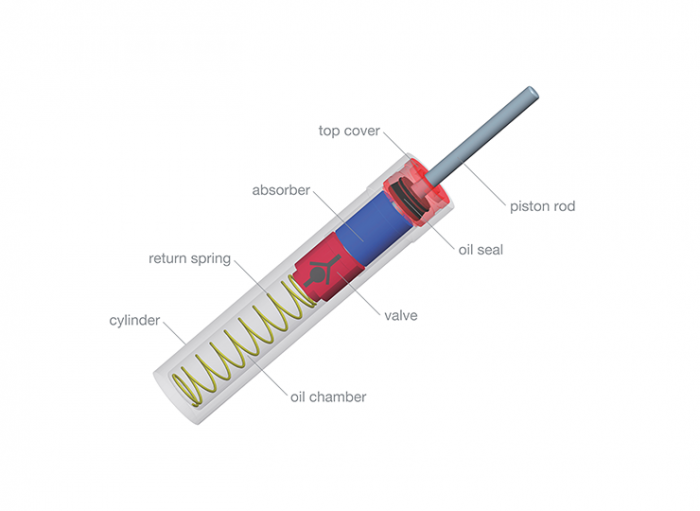

How does hydraulic damping technology work?

Titus dampers slow down linear or rotary movement before reaching a resting position.

By converting kinetic energy into thermal energy, hydraulic dampers reduce hard shocks and oscillation amplitudes. In a linear damper, the kinetic energy of the moving object is transferred through the steel rod to the valve in the damping cylinder. Hydraulic fluid is pushed through the valve and heat is generated. As the spring returns the valve to its original position, hydraulic fluid flows back into the damping chamber.

They have a longer life expectancy than a gas piston. The hydraulic damper has less tendency to re-bounce compared to air - dampers.

Why choose Titus damper?

- Modular design

- Support and service

- Safe & durable

- Over 15 years of damping experience

- We can deliver complete damping unit

- Customized damping solution

Guaranteed quality and performance

We guarantee the highest quality of our dampers. We manufacture them with high precision and with our proprietary assembly and quality assurance equipment. The automated assembly technology itself minimises variations in performance. We guarantee consistency over high-volume production runs with integrated 100% quality checks. Every damper is also laser-marked for complete traceability and lot control.

Download Catalog

For more detailed information and technical specifications, please download our catalog.

Talk to Our Experts

Looking for a soft-closing solution for your application? Our team designs and delivers custom damping solutions tailored to your needs.

Fill out the form and let’s start the conversation!

Need assistance?

If you need assistance or cannot find what you are looking for, feel free to send us an email to [email protected] and we will get back to you as soon as possible.

Subscribe to our Newsletter

Subscribe to receive news about our latest products and other updates.